GNTC student Miguel Lopez, a Dalton resident, works on a mechatronics trainer

Allan Curtis, a resident of Ringgold, tests a button on a screen while writing a program. Mr. Curtis attends classes at GNTC’s Whitfield Murray Campus in Dalton.

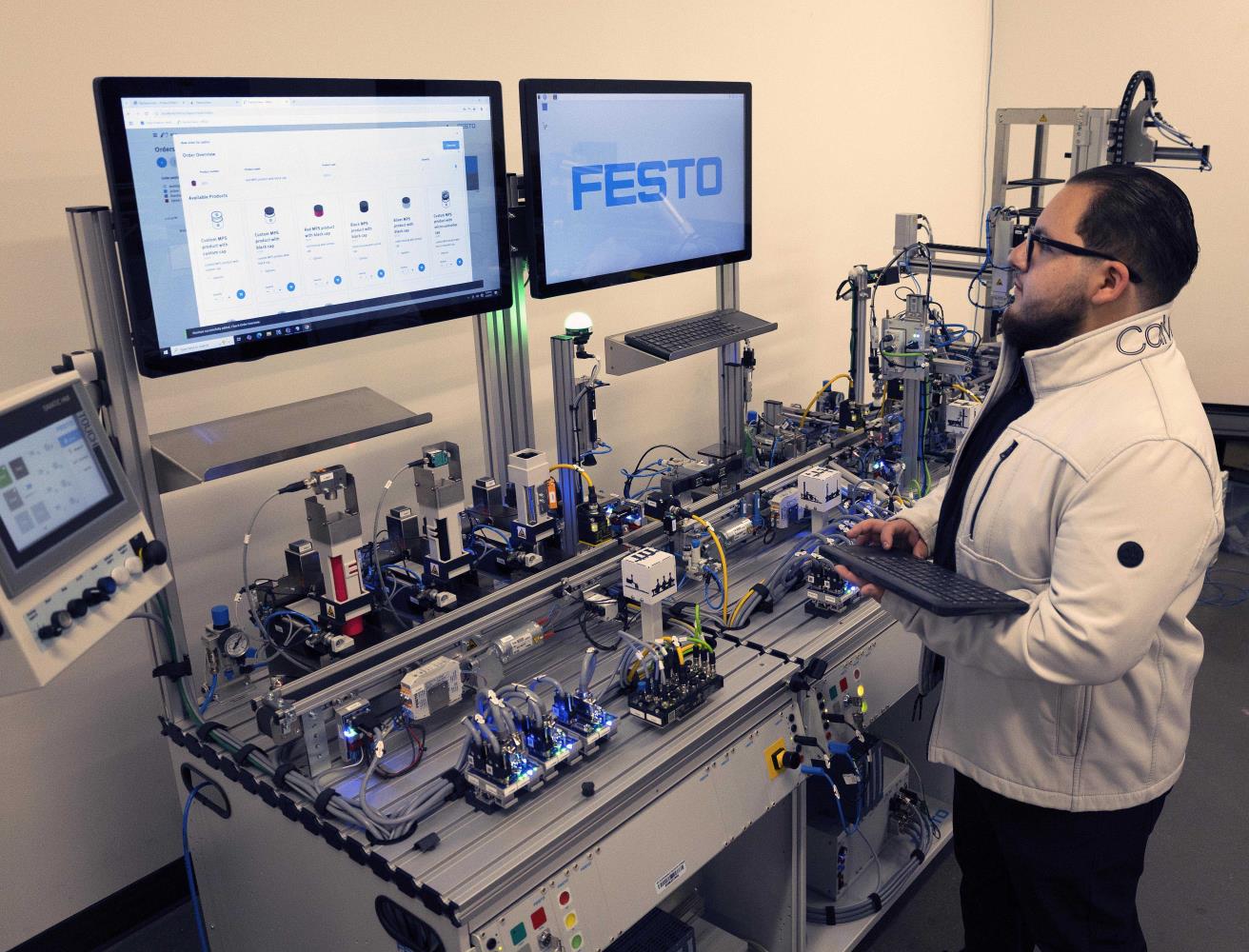

GNTC student Cris Jacobo of Chatsworth builds an automation trainer

Georgia Northwestern Technical College’s Automation Engineering Technology program prepares students to design, implement and troubleshoot automated industrial processes on robotic equipment and other automated systems.

The Automation Engineering Technology associate degree program, established in fall 2019, is housed at GNTC’s Whitfield Murray Campus in Dalton.

“A handful of other colleges in Georgia offer automation programs through Mechatronics, but GNTC’s program is the only engineering-based program.” said Darrell Huggins, GNTC’s Automation Engineering Technology program director and instructor.

“GNTC also has industry-standard equipment that allows students to learn current concepts relevant to the field.”

Automation Engineering is one of the fastest growing fields in the industry, Mr. Huggins said.

“Manufacturers see automation and the required jobs to keep everything running as investment priorities to speed up production and minimize costs,” Mr. Huggins said. “Most people usually think of automation as robotics, but it also extends into areas that many people don’t see, like medical, manufacturing, finance and customer service.”

Mr. Huggins said 3D printing has revolutionized manufacturing, enabling rapid prototyping and customized production. Cloud computing with seamless data storage and real-time analytics across locations and devices is also becoming more important as companies gather data on production processes.

GNTC’s program emphasizes math and physical science and features a strong occupational core encompassing circuit analysis, computer programming, CAD (computer aided design) and economics. Students learn motor theory and application, PLC (programmable logic controller) fundamentals and HMI (human machine interface) touchscreen programming, complex industrial instrumentation and loop tuning techniques, instrumentation calibration techniques and industrial robot programming.

At the end of the program, students either complete a capstone project or work as an engineering intern for a participating local company for eight to 10 weeks. The program also provides a path for students to enter into a bachelor’s degree program in engineering at another college.

“GNTC offers a dual degree option with Industrial Systems Technology that allows students to receive up to two associate degrees, one diploma and nine certificates while attending a two-year schedule,” Mr. Huggins said. (Industrial Systems Technology will become Automation Technology in Fall 2025.)

Todd Campbell, who works in medical robotics for Swiss company DIH Inc., earned the dual degree program in Automation Engineering and Industrial Systems Technology at GNTC.

Mr. Campbell attended classes in his 40s, seeking a career that would enable him to afford to care for his family more comfortably than he could if he started his own business. He said GNTC’s program provided a terrific opportunity.

“Automation Engineering is the future of the world and is a great platform to get your foot into the field or to create a career if you want to move into Mechatronics,” Mr. Campbell said. “Automation entails more than conveyors and assembly lines; it is used by water systems, airlines and numerous other industries.”

“I strongly suggest a dual degree in Automation Engineering and Industrial Systems Technology at GNTC because the core principles of both are the electronics and electrical side of things, which will help the graduate to excel in the field or move on to pursue a four-year degree,” Mr. Campbell said.

Graduates have a skill set that can take them in diverse career fields, including as automation rehabilitation equipment technicians in hospitals, engineering assistants in engineering departments, process control automation technicians in manufacturing, robotic repair and programming engineers, PLC and controls technicians and many positions in the automotive and the flooring industries, Mr. Huggins said. Employers who need graduates with this educational experience include Budweiser, Mars Inc. and Universal Studios, for example.

Graduates can earn from $55,000 to $100,000, based on experience, and receive great benefits, he said.

The career field pays well because graduates must be dedicated to learning, willing to spend years to master the wide range of concepts and equipment required, and prepared to cope with a lot of pressure, he said. Corporations lose thousands of dollars an hour when multimillion-dollar equipment is out of service, requires updates or needs repairs.

“In the last year, we have added three new robots and have a state-of-the-art Mechatronics automation system from Festo, which fully automates ordering,” Mr. Huggins said. “We have two Fanuc robots and one Universal robot.”

Employers who contact GNTC to hire employees are confident that graduates have the experience and expertise to work on their expensive equipment because they used some of the same machines at GNTC, he said.

Graduates of the program are in high demand across the United States and in many other countries, Mr. Huggins said. The demand is so great that GNTC students who have the hands-on skills have been hired by industry before they completed their physics course.

“We field anywhere from two to four and up to 10 requests per semester, depending on the economy. One company hired six students in two months before graduation,” Mr. Huggins said. “Some employers hire students as interns and pay for them to finish their program at GNTC.”

Mr. Huggins said he spent six years in the U.S. Air Force as a crew chief providing support for F-16CJ fighter jets. He later worked as an automotive technician at Ford and then owned his own repair shop for two years. Then he went to work in industrial maintenance.

After beginning the Mechanical Engineering program at another college, he transferred to GNTC, where he earned an associate degree in Industrial Systems Technology, he said. He earned a bachelor’s degree through Valdosta State University. In more than 20 years of maintenance experience, he has also earned several certifications from colleges and industries, such as Siemens, he said.

“Automation Engineering Technology isn’t a field for everyone; you need to enjoy solving problems,” Mr. Huggins said. “Engineering problems are a little more complicated than most. If you enjoy it, then it never feels like work. You create new things and accomplish something that everyone uses or needs. You feel rewarded because people rely on you.”